The differences between sheet metal stamping processing and hardware processing

In modern manufacturing, both sheet metal stamping processing and hardware processing are important production processes, but there are obvious differences between them.

I. Definition and Process

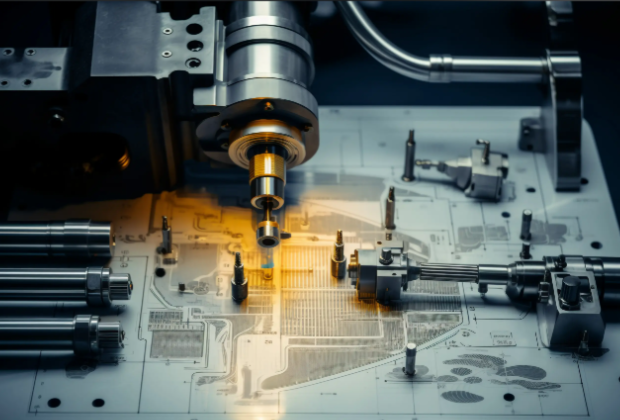

Sheet metal stamping processing mainly utilizes stamping equipment and dies to perform cold stamping on thin metal sheets, causing plastic deformation or separation, thereby obtaining parts of the required shape and size. Common sheet metal stamping processes include blanking, bending, stretching, etc. For instance, most of the components of a car body are made through sheet metal stamping processing.

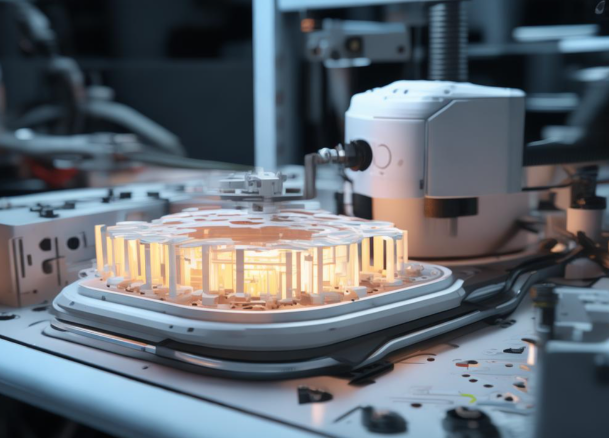

Metalworking encompasses a broader range of metal processing techniques, including cutting, casting, forging, welding, etc. Metalworking can process various metal materials, not limited to thin plates, but also including bars, tubes, etc. For instance, hardware tools, mechanical parts and the like are usually manufactured through hardware processing.

Ii. Scope of Application of Materials

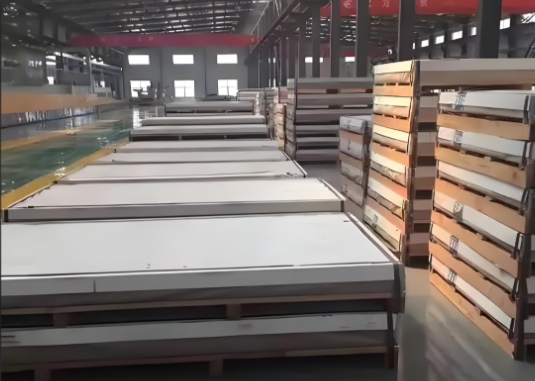

Sheet metal stamping processing is mainly applicable to thin metal sheet materials, such as steel plates, aluminum plates, copper plates, etc. These materials have good plasticity and processability, making them suitable for stamping deformation. Due to the thinness of the sheet, the thickness tolerance requirements for the material are relatively high during the processing.

Metalworking can be applied to various metal materials, including thick plates, profiles, castings, etc. Different metalworking techniques have different requirements for materials. For instance, cutting is suitable for materials with moderate hardness, while casting is suitable for metals with lower melting points.

Iii. Machining Accuracy

The precision of sheet metal stamping processing is relatively high, especially in large-scale production, where the dimensional accuracy and consistency of parts can be guaranteed through high-precision molds and stamping equipment. Generally speaking, the dimensional accuracy of sheet metal stamping parts can reach the millimeter level or even higher.

The precision of metalworking varies depending on the process. Cutting processing can achieve high precision, but for some parts with complex shapes, the processing difficulty is relatively high and the precision may be affected. The precision of processes such as casting and forging is relatively low, and subsequent processing is usually required to improve the precision.

Iv. Production Efficiency

Sheet metal stamping processing has a very high production efficiency and is suitable for large-scale production. Once the mold design and manufacture are completed, the stamping equipment can produce parts quickly and continuously, greatly shortening the production cycle.

The production efficiency of metalworking varies depending on the process. The cutting process is relatively slow, especially for the processing of complex parts, which requires a long time. Although casting and forging processes can form larger-sized parts in one go, the time for mold manufacturing and production preparation is relatively long.

V. Product Features

Products processed by sheet metal stamping usually have the following characteristics: regular shape, high dimensional accuracy, good surface quality and relatively high strength. As it is processed by cold stamping, the internal structure of the parts is tight and the mechanical properties are good.

The products of metalworking are more diverse and can be manufactured into parts of various shapes and properties according to different processes and requirements. For instance, cast parts can have complex internal structures, while forged parts possess excellent mechanical properties.

To sum up, there are obvious differences between sheet metal stamping processing and hardware processing in terms of definition and process, applicable scope of materials, processing accuracy, production efficiency and product features. In actual production, the appropriate processing technology should be selected based on specific product requirements and production conditions to achieve the best production effect.

Previous

Previous