Precautions for CNC machining of hardware

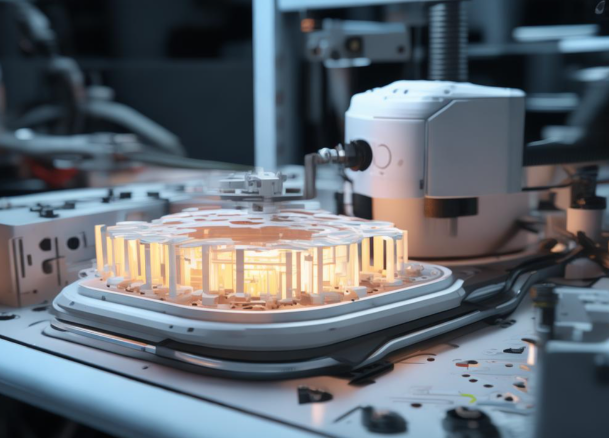

CNC machining of hardware is a high-precision and high-efficiency processing method. However, during the processing, some matters also need to be noted to ensure processing quality and production safety.

I. Programming Design

Accurate understanding of drawings: Before programming, carefully study the design drawings of hardware parts to ensure a clear understanding of requirements such as dimensions, tolerances, and shapes. Any misunderstanding may lead to processing errors.

Reasonable tool path planning: Based on the shape of the part and processing requirements, plan a reasonable tool path. This can reduce processing time, increase tool life, and ensure the quality of the machined surface. For instance, avoid unnecessary idle tool moves and choose the best way to feed in and withdraw the tool.

Consider the machining allowance: When programming, an appropriate machining allowance should be reserved to facilitate adjustments and corrections during subsequent processing. Excessive allowance may increase processing time and cost, while too little allowance may lead to incomplete processing or dimensional deviation.

Ii. Tool Selection

Appropriate tool type: Select the appropriate tool type based on the hardness, strength and processing requirements of the hardware material. For instance, for materials with high hardness, hard alloy cutting tools can be chosen. For processing parts with complex shapes, ball-end mills or fillet mills can be selected.

The quality and precision of cutting tools: Select cutting tools of good quality and high precision to ensure processing quality and tool life. Low-quality cutting tools may experience problems such as rapid wear and rough machined surfaces.

The size and length of the cutting tool: Select the appropriate size and length of the cutting tool based on the size of the part and the processing depth. If the tool is too long, it may cause vibration and unstable processing; if it is too short, it may not be able to process to the required depth.

Iii. Equipment Operation

Inspection and maintenance of equipment: Before conducting CNC processing of hardware, a comprehensive inspection and maintenance of the equipment should be carried out. Ensure that all components of the equipment are operating normally, the cutting tools are firmly installed, and there is sufficient coolant, etc. Regular maintenance and repair of equipment can extend its service life and improve processing accuracy.

Safety Operation Procedures: Strictly abide by the safety operation procedures of the equipment and wear necessary protective gear, such as safety helmets, goggles, gloves, etc. During the processing, it is necessary to pay close attention to the operating status of the equipment to avoid any unexpected accidents.

Setting of processing parameters: According to the nature of the hardware material and processing requirements, set processing parameters reasonably, such as cutting speed, feed rate, cutting depth, etc. Excessively high processing parameters may lead to rapid tool wear and rough processing surfaces, while excessively low processing parameters will affect processing efficiency.

Iv. Quality Control

First article inspection: Before conducting batch processing, first article inspection should be carried out first. Check whether the size, shape, surface quality, etc. of the first piece meet the requirements. If there are any problems, adjust the processing parameters or programs in time.

Process inspection: During the processing, regular process inspection should be carried out to check whether the processing quality of the parts is stable. If problems are found, the causes should be analyzed in a timely manner and corresponding measures should be taken.

Final inspection: After the parts are processed, a final inspection should be carried out. Comprehensively inspect whether the dimensions, shapes, surface quality, hardness, etc. of the parts meet the requirements to ensure that the quality of the parts complies with the standards.

V. Environmental Protection

Coolant treatment: Coolant is used in the CNC machining process of hardware. It is necessary to treat the coolant reasonably to avoid environmental pollution. Filtration, recycling and other methods can be adopted to reduce the waste and discharge of coolant.

Chip handling: A large amount of chips will be produced during the processing. It is necessary to clear the chips in time to avoid accumulation which may affect the operation of the equipment and the processing quality. Chips can be recycled or properly disposed of to reduce the impact on the environment.

In conclusion, when it comes to CNC machining of hardware, attention should be paid to issues such as programming design, tool selection, equipment operation, quality control and environmental protection. Only by strictly controlling every link can the processing quality and production safety be ensured and the production efficiency be improved.

Previous

Previous