SLS Selective Laser Sintering technology: An efficient and precise 3D printing solution

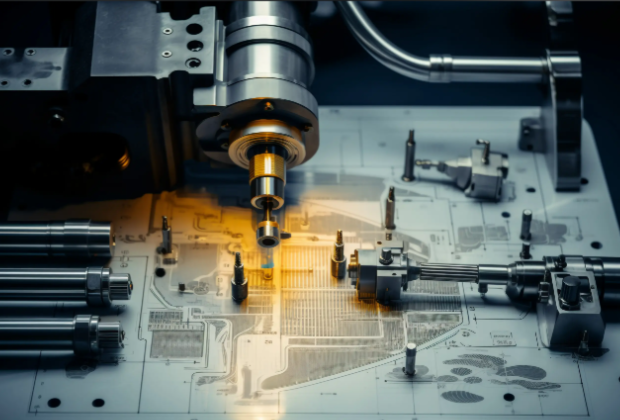

Selective Laser Sintering (SLS for short) is an advanced additive manufacturing technology that uses high-power lasers to selectively sinter powder materials and accumulate them layer by layer to form three-dimensional solid parts. This technology has developed since the 1980s and has become an important part of industrial-grade 3D printing.

Working principle

The workflow of SLS technology includes the following key steps:

Powder spreading stage: Evenly spread a very thin layer of powder material on the forming platform

Sintering process: Based on the CAD model slice data, the laser beam selectively scans and sinters the powder particles

Cooling and curing: The area after sintering cools and solidifies to form the cross-section of the part

Cyclic repetition: The platform descends, and the powder spreading and sintering processes are repeated until the part is fully formed

Technical advantage

1. Excellent processing performance

SLS technology features a high-precision standard of ±0.2mm/100mm, with a maximum forming size of 350×350×420mm, which can meet the size requirements of most industrial applications.

2. Rich material selection

Supports multiple engineering materials

Nylon series (FS3300PA) : It features excellent mechanical strength and wear resistance

Nylon glass fiber composite material (FS3400GF) : Offers higher rigidity and thermal stability

Special materials: including metals, ceramics and their composite materials

3. No supporting structure is required

The unsintered powder naturally supports the parts during the manufacturing process. This feature makes SLS particularly suitable for manufacturing:

(1) Complex internal cavity structure

(2) Nested assemblies

(3) Large overhang and inverted features

4. High material utilization rate

Unused powder can be recycled and reused, and the material utilization rate usually reaches over 95%, significantly reducing production costs.

Application field

Industrial manufacturing

Rapid verification of functional prototypes

Small-batch customized production

Manufacturing of complex tooling fixtures

Medical and health care

Personalized surgical guide plate

Bionic implant

Rehabilitation equipment

Aerospace

Lightweight structural components

Engine components

Aerodynamic test model

Automobile manufacturing

Complex components such as intake manifolds

Customized modification parts

Prototype production during the research and development stage

Technical challenges and development trends

Current challenges

The equipment cost and maintenance expenses are relatively high

The surface roughness needs to be further improved

The post-processing procedures are relatively complex

Future development direction

Multi-material printing: Achieving the integration of different materials in the same part

Large-scale equipment: Develop industrial-grade equipment with larger forming volumes

Intelligent control: Introduce artificial intelligence to optimize process parameters

Green Manufacturing: Further enhance material recycling rate and environmental friendliness

Conclusion

SLS selective laser sintering technology, as an important branch in the field of additive manufacturing, is reshaping the production methods of traditional manufacturing. Its unique technological features and broad application prospects make it one of the key technologies driving the digital transformation of the manufacturing industry. With the continuous advancement of materials science and process technology, SLS is bound to play a significant role in more fields, providing strong technical support for innovative design and intelligent manufacturing.

Previous

Previous