Analysis of Medical Prototype Shell Processing

In the field of medical equipment, the processing of handboard shells is of vital importance. It not only concerns the aesthetic appearance of medical equipment, but also directly affects its performance and reliability.

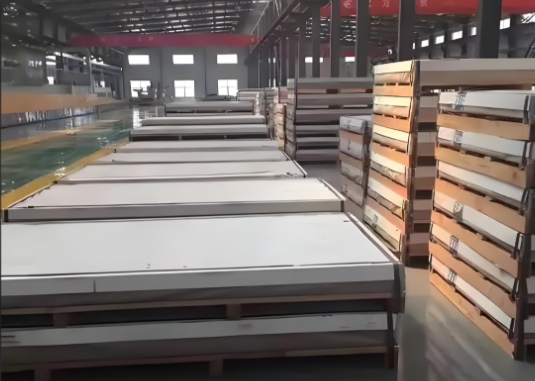

The first thing to pay attention to in the processing of medical prototype shells is the selection of materials. Materials with good mechanical properties, corrosion resistance and biocompatibility are generally selected. For instance, engineering plastics such as ABS, PC, and PP are of high strength and good toughness, capable of withstanding certain external impacts, and are also easy to process and shape. For some medical equipment with special requirements, metal materials such as aluminum alloy and stainless steel may also be selected to meet higher strength and precision requirements.

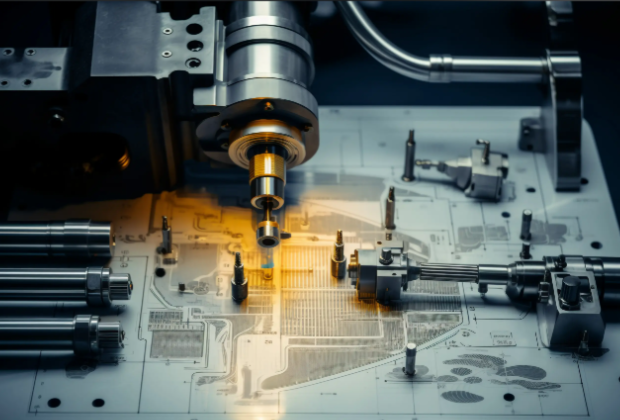

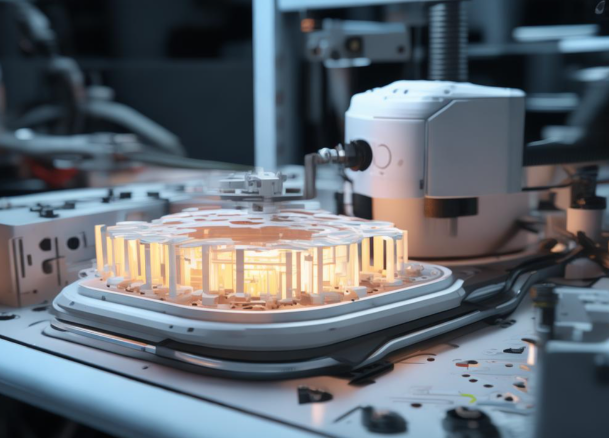

In terms of processing techniques, it mainly includes CNC machining, injection molding, 3D printing, etc. CNC machining features high precision and high efficiency, and can precisely process various complex-shaped handboard shells according to design drawings. By programming and controlling the movement trajectory of the cutting tool, operations such as cutting, drilling and milling of materials can be achieved, thereby obtaining a handboard shell with high dimensional accuracy and good surface quality. Injection molding is suitable for mass production. It can quickly manufacture handboard shells with consistent shapes and stable dimensions. First, make a mold, then inject the molten plastic material into the mold. After cooling and solidification, the finished product can be obtained. 3D printing technology has also been widely applied in the processing of medical prototype shells in recent years. It can quickly produce complex geometric shapes and can be customized according to the specific needs of patients.

Quality control during the processing is also a key link. The dimensional accuracy must be strictly controlled to ensure the assembly accuracy between the handboard shell and the internal components. By using precise measuring tools, such as three-coordinate measuring machines, etc., the dimensions of the processed handboard shell are inspected to promptly identify and correct dimensional deviations. At the same time, attention should also be paid to the surface quality to avoid defects such as scratches, burrs and shrinkage marks. These defects not only affect the appearance but may also impact the performance and safety of medical equipment.

In addition, the design of the medical prototype shell also plays an important guiding role in processing. Reasonable design can simplify processing techniques, reduce costs and improve production efficiency. During the design process, the usage environment and functional requirements of medical equipment should be fully considered to determine the appropriate shape, size and structure of the shell. At the same time, the feasibility of the processing technology should also be considered to avoid designing overly complex structures that are difficult to process.

In conclusion, the processing of medical prototype shells is a complex and meticulous process that requires comprehensive consideration of multiple aspects such as material selection, processing technology, quality control, and design. Only through strict processing management and quality control can high-quality and high-performance medical handboard shells be produced, providing strong support for the research and development and production of medical equipment.

Previous

Previous