Detailed Explanation of CNC Machining for Aluminum Alloy Prototypes

Aluminum alloy prototypes are widely used in product development and manufacturing due to their advantages such as light weight, high strength and corrosion resistance. CNC machining technology provides a high-precision and high-efficiency processing method for the production of aluminum alloy prototypes.

I. Advantages of CNC Machining

High precision: CNC processing equipment can achieve extremely high processing accuracy, which can meet the requirements of projects with high demands for the dimensional accuracy and surface quality of aluminum alloy prototypes.

High efficiency: The automated processing procedure significantly enhances production efficiency, reducing the time and errors of manual operation.

Complex shape processing: It can easily process various complex geometric shapes to meet the design requirements of different products.

Good consistency: Due to the use of numerical control programming to control the processing process, it can ensure that the aluminum alloy prototypes produced in batches have a high degree of consistency.

Ii. Main Processes of CNC Machining for Aluminum Alloy Prototypes

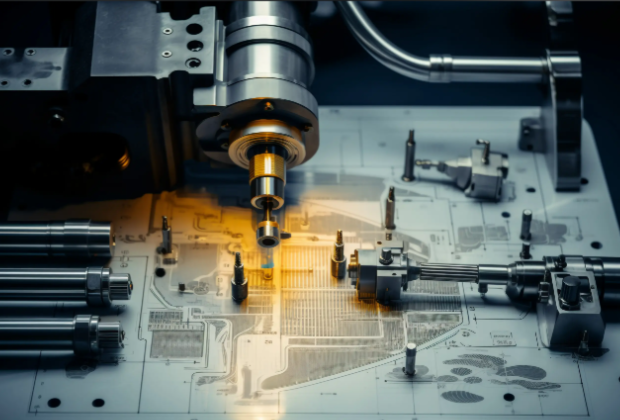

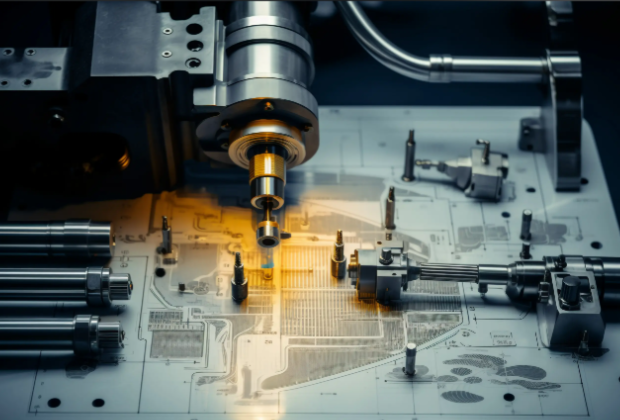

Milling machining

Plane milling: It is used for processing the flat part of aluminum alloy prototypes and can obtain a smooth and flat surface.

Contour milling: According to the design requirements, precisely process the external contour of the aluminum alloy prototype.

Cavity milling: It is used for processing grooves, cavities and other structures inside handboards.

Drilling processing

Ordinary drilling: Various diameters of holes are machined on aluminum alloy prototypes to meet the requirements of assembly and connection.

Deep hole drilling: For some handboards that require relatively deep holes, specialized deep hole drilling technology is adopted.

Tapping processing

Tapping is carried out on the basis of drilling to process internal threads, which is convenient for connection with other components.

Engraving processing

The CNC engraving machine can be used to perform fine engraving on the surface of aluminum alloy prototypes, adding decorative elements such as text and patterns.

Iii. Processing Procedure

Design and Programming

According to the product design drawings, 3D modeling and numerical control programming are carried out using professional CAD/CAM software.

Determine the processing technology parameters, such as cutting speed, feed rate, tool path, etc.

Material preparation

Select the appropriate aluminum alloy material and ensure that its quality and performance meet the requirements.

Cut the aluminum alloy material to the appropriate size for processing.

Clamping and positioning

Fix the aluminum alloy material on the worktable of the CNC processing equipment to ensure that it does not move or deform during the processing.

Use precise positioning devices to ensure the accuracy of processing.

Processing operation

Start the CNC machining equipment and process according to the programmed tool path.

During the processing, operators should closely monitor the operating status of the equipment, adjust the processing parameters in a timely manner, and ensure the processing quality.

Quality inspection

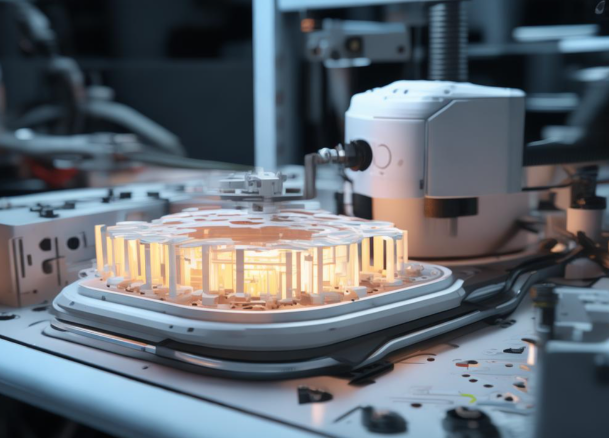

After processing is completed, a comprehensive quality inspection is carried out on the aluminum alloy prototype.

Check whether the dimensional accuracy, surface quality, hole position accuracy and other indicators meet the design requirements.

Surface treatment

According to requirements, surface treatments such as anodizing and spraying are carried out on aluminum alloy prototypes to enhance their appearance quality and corrosion resistance.

Iv. Precautions

Tool selection: Based on the material of the aluminum alloy and processing requirements, choose the appropriate tool to ensure processing efficiency and quality.

Cutting parameter optimization: Reasonably adjust parameters such as cutting speed and feed rate to avoid excessive heat generation and tool wear.

Cooling and lubrication: During the processing, appropriate cooling and lubricating fluids should be used to lower the cutting temperature and extend the tool life.

Quality control: Strengthen the quality control during the processing, promptly identify and solve problems, and ensure the quality of aluminum alloy prototypes.

In conclusion, CNC machining of aluminum alloy prototypes is an efficient and precise processing method. Through reasonable process design and strict quality control, high-quality aluminum alloy prototypes can be produced, providing strong support for product development and manufacturing.

Previous

Previous