A thorough analysis of the surface treatment process of stamping sheet metal

In today's manufacturing industry, stamping sheet metal parts are widely used in various fields. However, in order to enhance the corrosion resistance, aesthetic appeal and wear resistance of stamped sheet metal parts, surface treatment processes have become an indispensable part. This article will delve deeply into the surface treatment process of stamping sheet metal, taking you to explore the mysteries of this field.

I. The Importance of Surface Treatment Processes

The surface treatment process of stamping sheet metal parts not only enhances their aesthetic appeal but also provides additional protection, making them less prone to corrosion and wear in harsh environments. In addition, a good surface treatment process can also enhance the electrical conductivity, thermal conductivity and weldability of sheet metal parts, meeting the specific requirements of the products.

Ii. Common Surface Treatment processes

Spraying

Spraying is a process in which paint is evenly applied to the surface of sheet metal parts. It can offer a wide range of color options and form a strong coating, serving both anti-corrosion and decorative purposes. Phosphating treatment is usually required before spraying to enhance the adhesion of the coating.

Electrophoretic coating

Electrophoretic painting is a process in which paint is deposited on the surface of sheet metal parts under the influence of an electric field. Compared with spraying, electrophoretic coating has the advantages of uniform coating, strong adhesion and good corrosion resistance. It is often used in industries such as automobiles and home appliances.

Galvanizing

Galvanizing is a commonly used surface treatment method. It involves immersing sheet metal parts in a zinc solution to form a galvanized layer on their surface. The galvanized coating not only prevents corrosion but also has good wear resistance and electrical conductivity.

Powder coating

Powder coating is a process in which powder coatings are electrostatically adsorbed onto the surface of sheet metal parts and then heated to cure and form a coating. Powder coating has the advantages of being solvent-free, pollution-free and having uniform coating thickness, and is suitable for fields with high environmental protection requirements.

Iii. Selection of Surface Treatment Processes

When choosing a surface treatment process, multiple factors need to be considered, including the application of the product, the usage environment, cost, etc. Here are some suggestions for choosing surface treatment processes:

Choose according to the product's purpose

If the product requires good corrosion resistance and decorative properties, spraying, electrophoretic coating or galvanizing may be better choices. For some products with high requirements for electrical conductivity, powder coating may be more suitable.

Consider the usage environment

In harsh environments, such as by the seaside or in chemical industrial parks, surface treatment processes with better corrosion resistance, such as galvanizing or electrophoretic coating, need to be selected.

Cost factor

The costs of different surface treatment processes vary, and the choice should be made based on the budget. Under the premise of meeting the product quality requirements, try to choose an economical and cost-effective process as much as possible.

Iv. Quality Control of Surface Treatment Processes

To ensure the quality of the surface treatment process, strict quality control is required. This includes the inspection of raw materials, monitoring during the production process, and testing of the final product. In addition, the skills and experience of the operators also have a significant impact on the quality of the process.

V. Future Development Trends

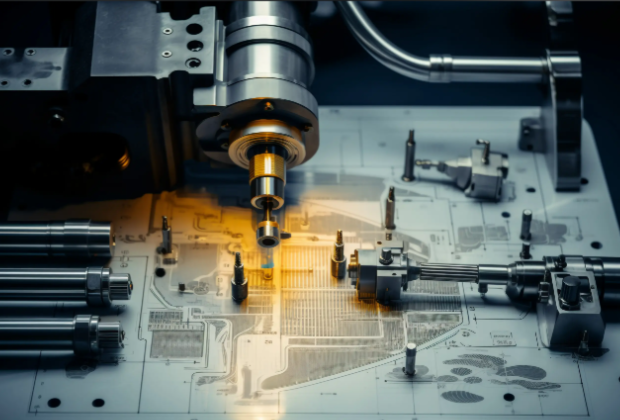

With the continuous advancement of technology, surface treatment processes are also constantly evolving. For instance, new types of eco-friendly coatings and surface treatment technologies are constantly emerging to meet increasingly strict environmental protection requirements. Meanwhile, intelligent surface treatment equipment will enhance production efficiency and quality stability.

In conclusion, the surface treatment process of stamping sheet metal is a complex and important field. By choosing the appropriate process and implementing strict quality control, the performance and appearance quality of stamped sheet metal parts can be enhanced to meet market demands. It is hoped that this article can provide you with some help in understanding the surface treatment process of stamping sheet metal.

Previous

Previous