Practical strategies and techniques for improving the accuracy of handboard models

In today's manufacturing industry, the production of handboard models plays a crucial role. The handboard model is an important prototype in the product design process. It not only helps designers verify the feasibility and appearance of the design, but also provides accurate references for subsequent production. However, for the production of handboard models, precision is a crucial indicator. So, what exactly are the requirements for precision in the production of handboard models?

The precision requirements for handboard model making mainly include the following aspects:

Dimensional accuracy: The dimensional accuracy of the handboard model directly affects the assembly and use of the product. Generally speaking, the dimensional accuracy of handboard models should be controlled within ±0.1mm. For some high-precision products, even higher accuracy is required.

Shape accuracy: The shape accuracy of the handboard model directly affects the appearance and performance of the product. Generally speaking, the shape accuracy of handboard models should be controlled within ±0.2mm. For some complex shapes, the accuracy requirements will be even higher.

Surface quality: The surface quality of the handboard model directly affects the appearance and performance of the product. Generally speaking, the surface quality of handboard models should reach Ra3.2 or above. For some high-precision products, even higher surface quality is required.

So, how can the precision requirements for handboard model making be met? This requires approaches from multiple aspects, including:

Select the appropriate material: Different materials have different physical and processing properties. Therefore, when choosing materials, it is necessary to select the appropriate material based on the purpose and precision requirements of the handboard model.

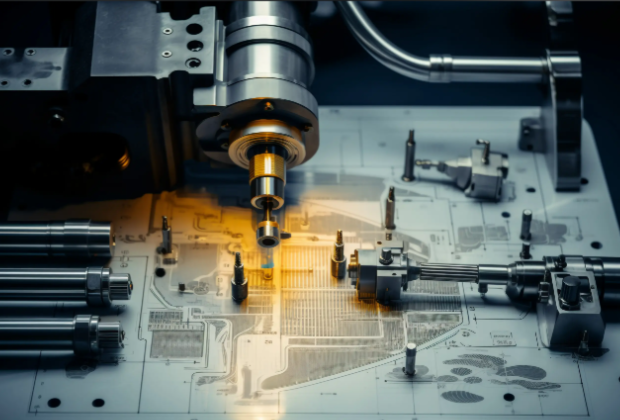

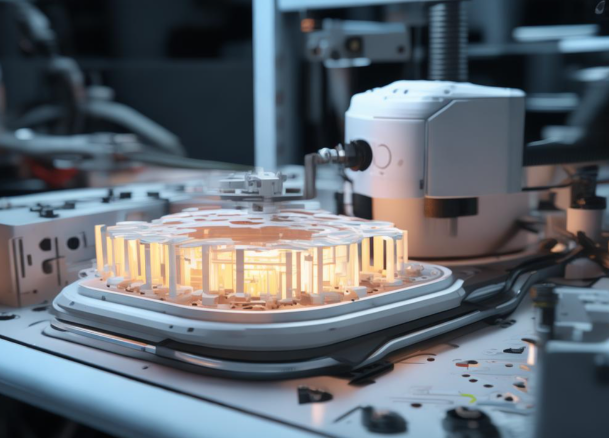

Adopt advanced processing equipment: The processing accuracy and efficiency of the handboard model directly depend on the performance of the processing equipment. Therefore, when making handboard models, advanced processing equipment such as CNC machine tools and 3D printers need to be adopted.

Optimizing processing technology: The optimization of processing technology is the key to improving the accuracy of handboard models. When making handboard models, it is necessary to optimize the processing technology based on the characteristics of the material and the performance of the processing equipment, such as choosing appropriate cutting tools and cutting parameters.

Carry out strict quality control: The quality control of handboard models is an important link to ensure accuracy. When making handboard models, strict quality control is required, including the inspection of raw materials, the monitoring of the processing process, and the inspection of finished products, etc.

In the actual process of making handboard models, some detailed issues also need to be noted, such as:

Maintain a stable processing environment: Factors such as temperature and humidity in the processing environment can affect the accuracy of the handboard model. Therefore, when making handboard models, it is necessary to maintain a stable processing environment.

Reasonable arrangement of processing sequence: A reasonable arrangement of processing sequence can reduce processing deformation and errors. When making handboard models, it is necessary to reasonably arrange the processing sequence according to the shape and precision requirements of the parts.

Strengthen the training of operators: The skills and experience of operators also have a significant impact on the accuracy of the handboard model. Therefore, when making handboard models, it is necessary to enhance the training of operators and improve their skills and experience.

In conclusion, the precision requirements for handboard model making are extremely high. It is necessary to take multiple approaches and adopt a series of measures to ensure accuracy. Only in this way can a handboard model that meets the requirements be produced, providing strong support for the design and production of the product.